Our Process

1. Assessment of Requirements

2. Quotation and Estimate

3. Glass Selection

4. Tempering Process

5. Customization

6. Client Satisfaction

We are a Miami-based company dedicated to the art of transforming glass into masterpieces of both form and function. With a relentless pursuit of perfection, we combine cutting-edge technology with skilled craftsmanship to deliver tempered glass solutions that exceed expectations.

How does Glass Tempering Works?

After a piece of glass has been fabricated, it is ready to be tempered. Here is a closer look at each step and its unique purpose.

Cutting

The first step is to cut the glass into the desired shape. Fabrication, such as edging or etching, must be completed before tempering, or the integrity of the final process could be compromised.

Pencil Ground Edges

Diamond embedded grinding wheels put a satin finish on the edge, with an edge radius similar to pencil or C-shape.

Pencil Polished Edges

Edges are polished to a sheen finish, with radius similar to pencil or C-shape.

Safety Seamed Edge

Swiped & Chamfered Edges

A sanding belt is used to lightly sand off the sharp edge of the glass.

Dubbed Corners

Chamfered or Radius Corner

The sharp edge of each corner can be nubbed or broken as required.

Stepped and Route Surfaces

Glass is ground away to leave a step or lip.

Beveled Edges

3 Styles

Ground or polished bevels on glass or mirror, circles, rectangles to any degree can be provided.

Bullnose Edge

HALF & FULL

These are typically polished edges (can be ground if required) that are similar to pencil edges, the difference being that the bullnose edge is a full radius curve where the diameter matches the thickness of the glass substrate. There are specific profiles where the relief angles can be different, typically where aesthetics are important or for critical applications where the edge of the glass could affect functionality.

HALF BULLNOSE

FULL BULLNOSE

Rapid Cooling

The glass undergoes a rapid-fire, high-pressure cooling procedure. This process lasts just seconds, as air blasts from a precisely-placed array of nozzles quickly cool the outer surfaces of the glass.

As the center cools, it tries to pull back, which leaves it in tension while the outer surface is in compression. This dichotomy is what gives tempered glass its impressive strength.

Cutting

The first step is to cut the glass into the desired shape. Fabrication, such as edging or etching, must be completed before tempering, or the integrity of the final process could be compromised.

Pencil Ground Edges

Diamond embedded grinding wheels put a satin finish on the edge, with an edge radius similar to pencil or C-shape.

Pencil Polished Edges

Edges are polished to a sheen finish, with radius similar to pencil or C-shape.

Safety Seamed Edge

Swiped & Chamfered Edges

A sanding belt is used to lightly sand off the sharp edge of the glass.

Dubbed Corners

Chamfered or Radius Corner

The sharp edge of each corner can be nubbed or broken as required.

Stepped and Route Surfaces

Glass is ground away to leave a step or lip.

Beveled Edges

3 Styles

Ground or polished bevels on glass or mirror, circles, rectangles to any degree can be provided.

Bullnose Edge

HALF & FULL

These are typically polished edges (can be ground if required) that are similar to pencil edges, the difference being that the bullnose edge is a full radius curve where the diameter matches the thickness of the glass substrate. There are specific profiles where the relief angles can be different, typically where aesthetics are important or for critical applications where the edge of the glass could affect functionality.

HALF BULLNOSE

FULL BULLNOSE

Rapid Cooling

The glass undergoes a rapid-fire, high-pressure cooling procedure. This process lasts just seconds, as air blasts from a precisely-placed array of nozzles quickly cool the outer surfaces of the glass.

As the center cools, it tries to pull back, which leaves it in tension while the outer surface is in compression. This dichotomy is what gives tempered glass its impressive strength.

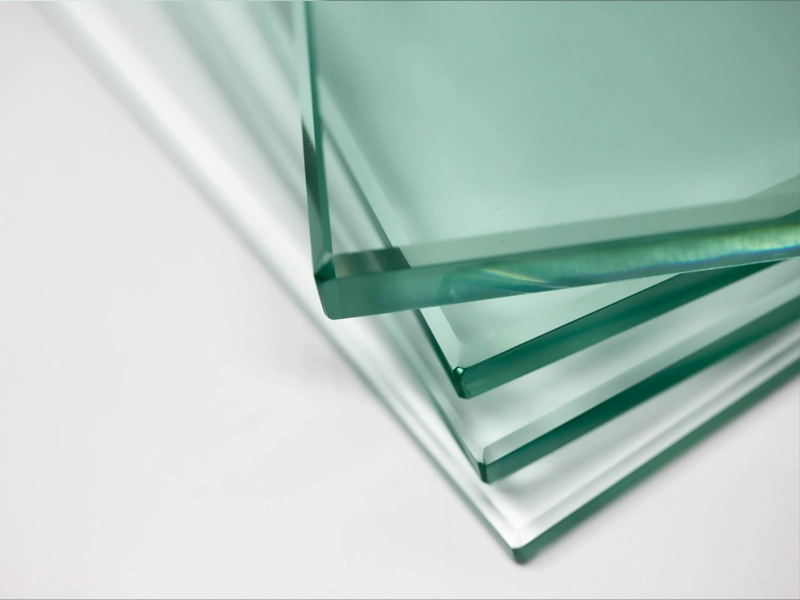

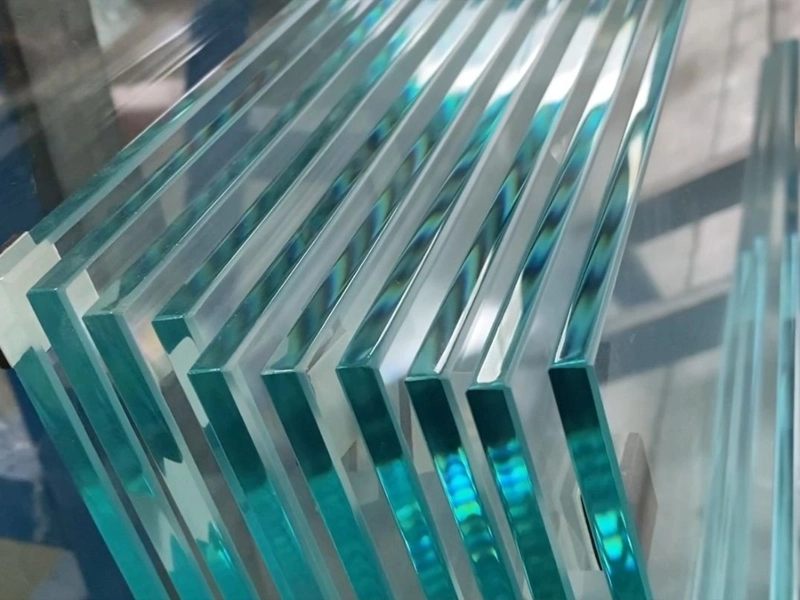

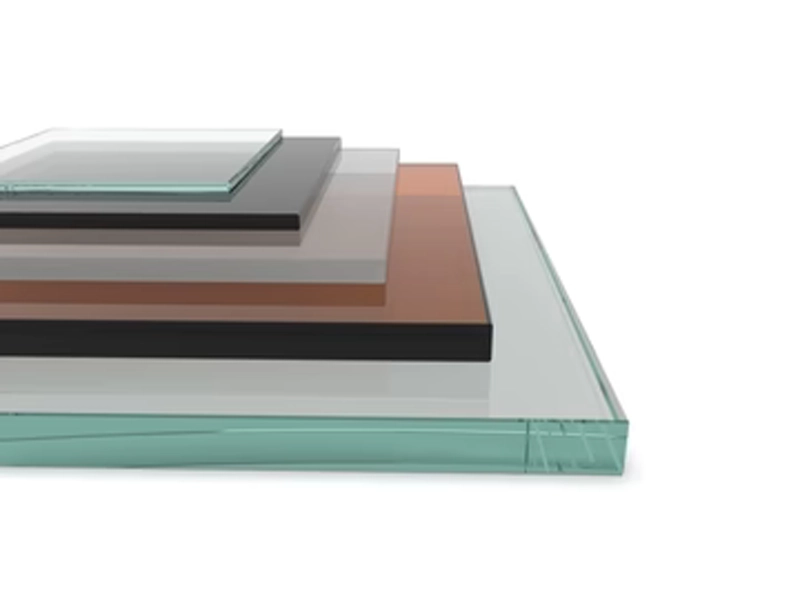

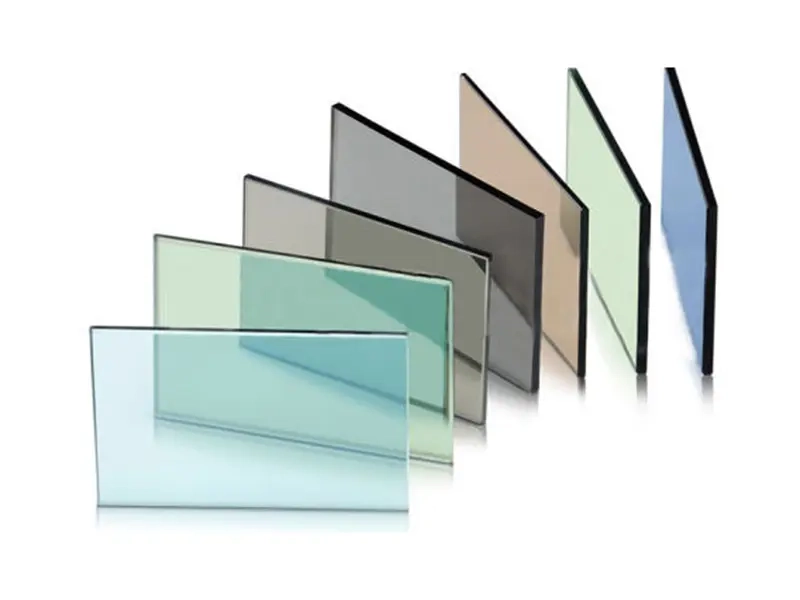

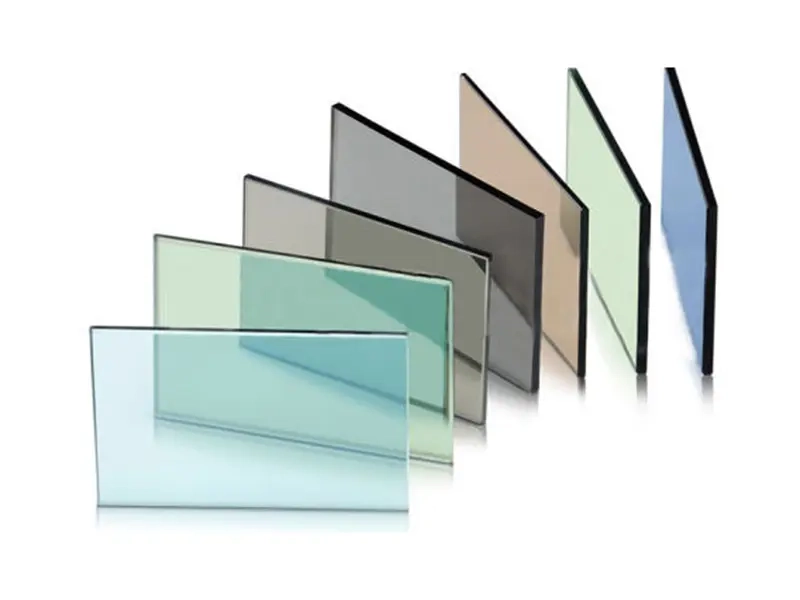

Types of Glass

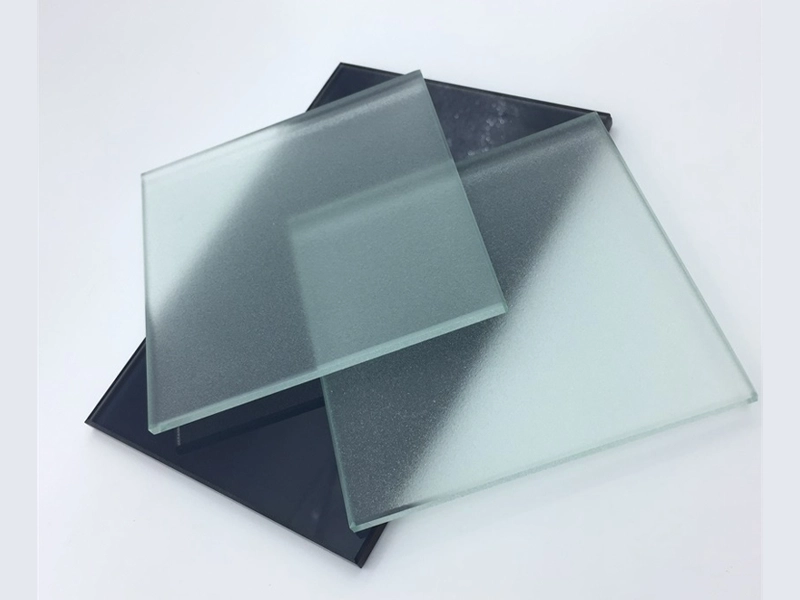

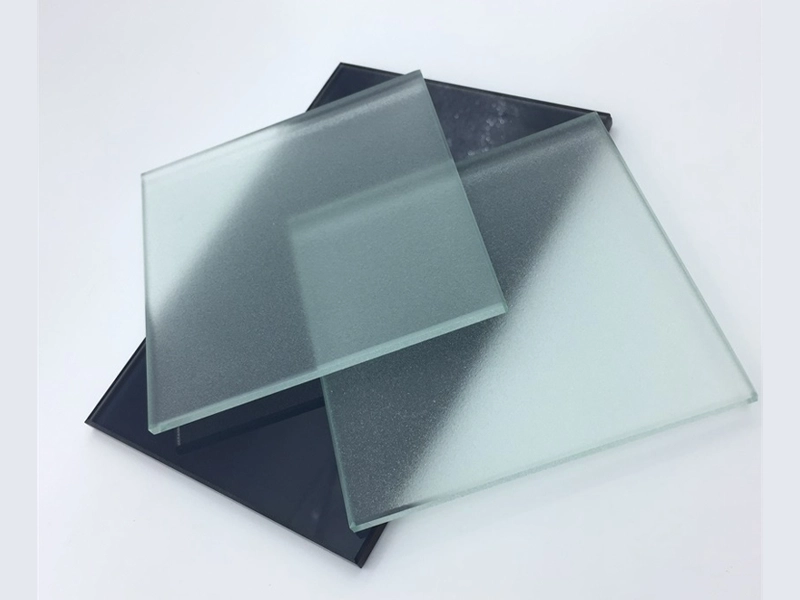

Clear

Sleek and transparent, perfect for a modern aesthetic with added strength for safety.

Tinted

Explore a spectrum of tints, from subtle to bold, combining style with UV protection.

Frosted

Introduce privacy and elegance with frosted tempered glass, ideal for doors and partitions.

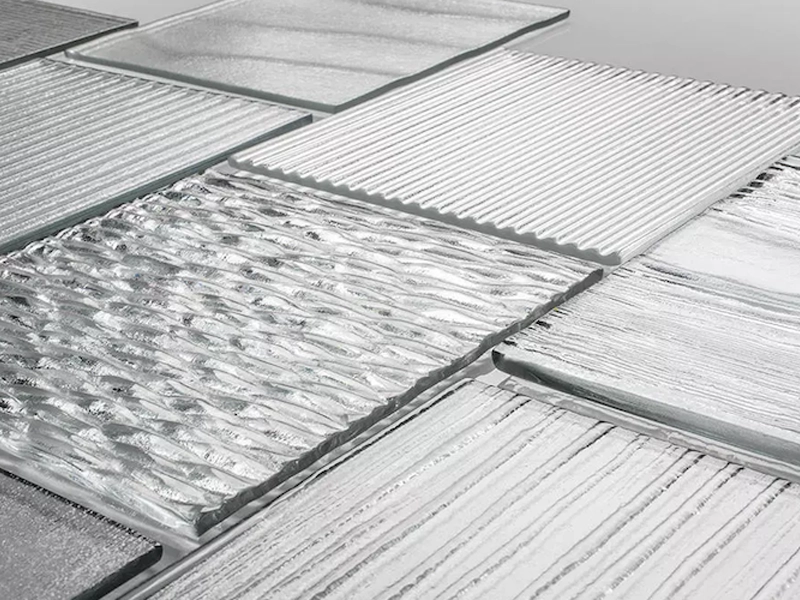

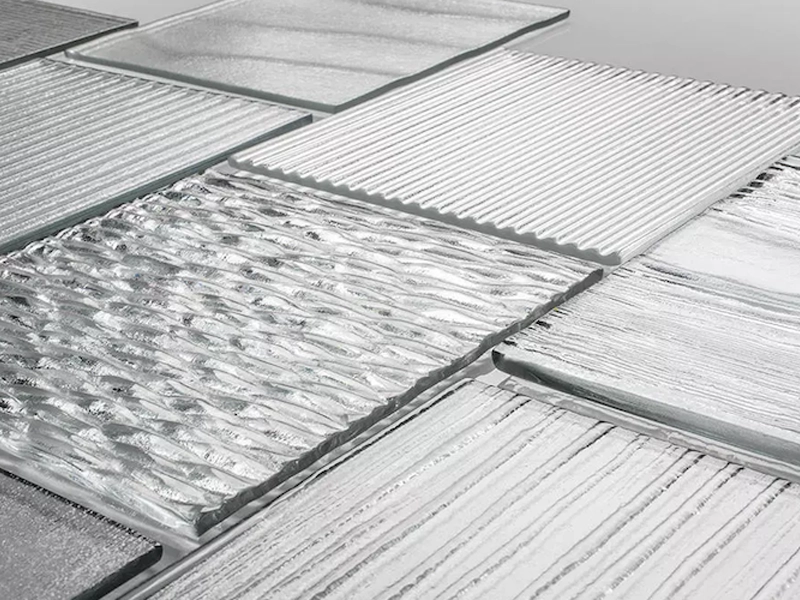

Patterned and Textured Styles

Elevate design with intricate patterns and textures, enhancing visual interest and uniqueness.

Custom Colors and Thickness

Tailor glass to your vision with custom colors and varied thickness options for ultimate versatility.

Luxe Glass Solutions aims to redefine the standards of tempered glass manufacturing, seamlessly blending innovation, quality craftsmanship, and customization to provide clients with unparalleled solutions that elevate the aesthetic and functional aspects of their spaces.

Contact Us!